The modern age has seen a revolution in the materials used to construct trucks and truck trailers. From steel to aluminum extrusions, these materials provide superior strength and durability while remaining lightweight.

With their revolutionary design, aluminum extrusions are changing the way we think about trucking and transportation. In this article, we will explore how aluminum extrusions are transforming the industry with their unique capabilities.

We’ll discuss the advantages of using them over traditional materials such as steel and look at some examples of projects that have been made possible due to these innovative designs. Finally, we’ll examine how this new technology is helping reduce costs for truckers around the world while improving safety standards on our roads.

The Advantages of Aluminum Extrusions for Trucks and Truck Trailers

Source: www.wileymetal.com

Aluminum extrusions are a lightweight yet incredibly strong alternative to traditional steel-framed truck and trailer construction, revolutionizing the way they’re built. Using aluminum instead of steel reduces overall weight by up to 30%, providing an increase in payload capacity while also reducing fuel costs. The strength and durability of aluminum extrusions provide drivers with peace of mind when hauling heavier loads over difficult terrain, as well as increased corrosion resistance for extended life.

Depending on the application, aluminum extrusions can be designed for specific axle configurations or attachment points, making it easier than ever to customize trailers without sacrificing quality or performance. Additionally, aluminum is easy to work with and offers superior weldability compared to other metals like stainless steel or galvanized steel, allowing greater flexibility in design options.

With all these advantages combined – reduced weight resulting in improved fuel efficiency and higher payloads; enhanced strength and durability; ease of customization; better weldability – it’s no wonder why more trucking companies are turning towards aluminum extrusions for their trucks and trailers!

How Lightweight and Strong Aluminum Extrusions are Revolutionizing the Industry

Aluminum extrusions have revolutionized the truck and trailer industry by providing a lightweight yet strong material that can be used to build stronger, more efficient structures. Extruded aluminum is formed through a process of forcing metal alloy through an extrusion die with high pressure and heat. While this method has been around since the late 19th century, it wasn’t until recently that its use in the truck and trailer industry become popular due to its ability to provide strength without adding too much weight.

By using extruded aluminum for load-bearing components on trucks and trailers, manufacturers can reduce overall weight while still maintaining structural integrity and durability. The use of aluminum extrusions also offers additional advantages such as improved aerodynamics which helps cut down on fuel costs; increased payload capacity due to better load distribution; improved corrosion resistance compared to other metals; lower production costs thanks to faster fabrication times; and reduced maintenance requirements over time due to superior longevity.

These features make them perfect for commercial applications where efficiency is key but cost savings are just as important. In short, lightweight yet strong aluminum extrusions are revolutionizing the trucking industry by offering greater efficiencies while reducing overall costs at the same time – making them a valuable asset in any fleet operation!

Benefits of Switching to Aluminum Extrusions for Heavy-Duty Vehicles

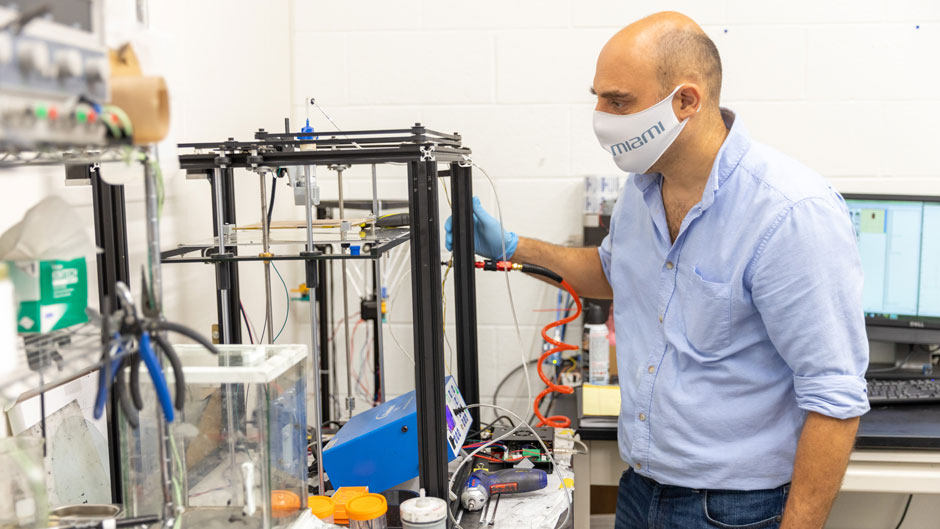

Source: news.miami.edu

Aluminum extrusions offer many beneficial advantages when used in heavy-duty vehicles. There are several reasons why one should consider switching to aluminum extrusions for truck and trailer needs.

First, they are incredibly lightweight which leads to improved fuel efficiency and reduced emissions due to the decreased weight of the vehicle. Second, aluminum is strong – it has a higher strength-to-weight ratio than other materials used in vehicle construction making it ideal for carrying heavier loads over long distances or down rough terrain.

Thirdly, aluminum extrusions can be customized easily with various anodized finishes that resist corrosion and look more aesthetically appealing than steel alternatives. Finally, because of its versatility as a material, aluminum can be manufactured into almost any shape or design depending on individual requirements meaning that truck trailers can be tailored to meet specific needs while remaining lightweight and strong at the same time.

Reducing Weight with Innovative Aluminum Solutions for Truck Bodies

To reduce the weight of truck bodies, aluminum extrusions are revolutionizing the industry. By replacing steel components with lightweight yet strong aluminum solutions, trucks, and trailers become much more fuel efficient while still maintaining their strength.

Ultimately, this means that manufacturers can produce lighter yet stronger vehicles at a lower cost without sacrificing performance or safety. Aluminum is an ideal material for many applications in the automotive industry due to its ability to form complex shapes and withstand extreme temperatures.

Moreover, it has been proven to be highly durable and corrosion-resistant even under harsh conditions such as road salt or mud during off-road use. When compared to steel alternatives, aluminum extrusions have significantly reduced maintenance costs over time due to their superior longevity.

Advanced extrusion technology enables engineers to craft unique designs which optimize fuel efficiency without compromising payload capacity or durability. This allows truck body makers and trailer builders alike the flexibility they need for customization purposes while also providing them with innovative ways of reducing the overall weight of vehicles on the road today.

The benefits of using aluminum over traditional materials don’t end there – these revolutionary solutions also make it easier for vehicle owners to customize their trucks or trailers according to their individual needs by allowing them to accessorize quickly and easily without having any welding expertise required to get things done right away! Thanks to these advantages provided by cutting-edge metal fabricating techniques utilizing Aluminum Extrusions, companies who manufacture heavy-duty transportation equipment are now able to create reliable pick-up beds, dumpster boxes, etc., that provide just enough strength needed along with minimal weight gain!

Source: www.pbclinear.com

Conclusion

Aluminum extrusion manufacturer are revolutionizing the truck and trailer industries, providing an innovative lightweight yet strong option for manufacturing. Aluminum is becoming increasingly popular due to its resistance to corrosion and its ability to be molded into intricate shapes.

With aluminum extrusion, manufacturers can create custom designs that meet their needs while offering an exceptional strength-to-weight ratio. This has allowed companies such as ABC Aluminum Extrusion Manufacturing Co., Inc., a leading manufacturer of aluminum extrusion products in North America, produce superior trucks and trailers with remarkable durability.

As aluminum continues to gain popularity among manufacturers, expect more vehicles on the market built with this advanced material technology in the future.