The production of starter motors is a significant contributor to environmental impacts, yet many companies lack the understanding of how best to incorporate recycling and sustainability practices. This article will explore the importance of incorporating these practices in starter motor production in order to reduce their effect on our environment.

It will also discuss how organizations can implement strategies that ensure their products are produced responsibly while remaining competitive in the market.

Finally, it will provide examples from actual businesses that have successfully adopted sustainability-focused initiatives within their motor production process.

With this information, readers can gain an understanding of how they too can help protect our planet through sustainable methods of producing starter motors.

Benefits of Recycling in Starter Motor Production

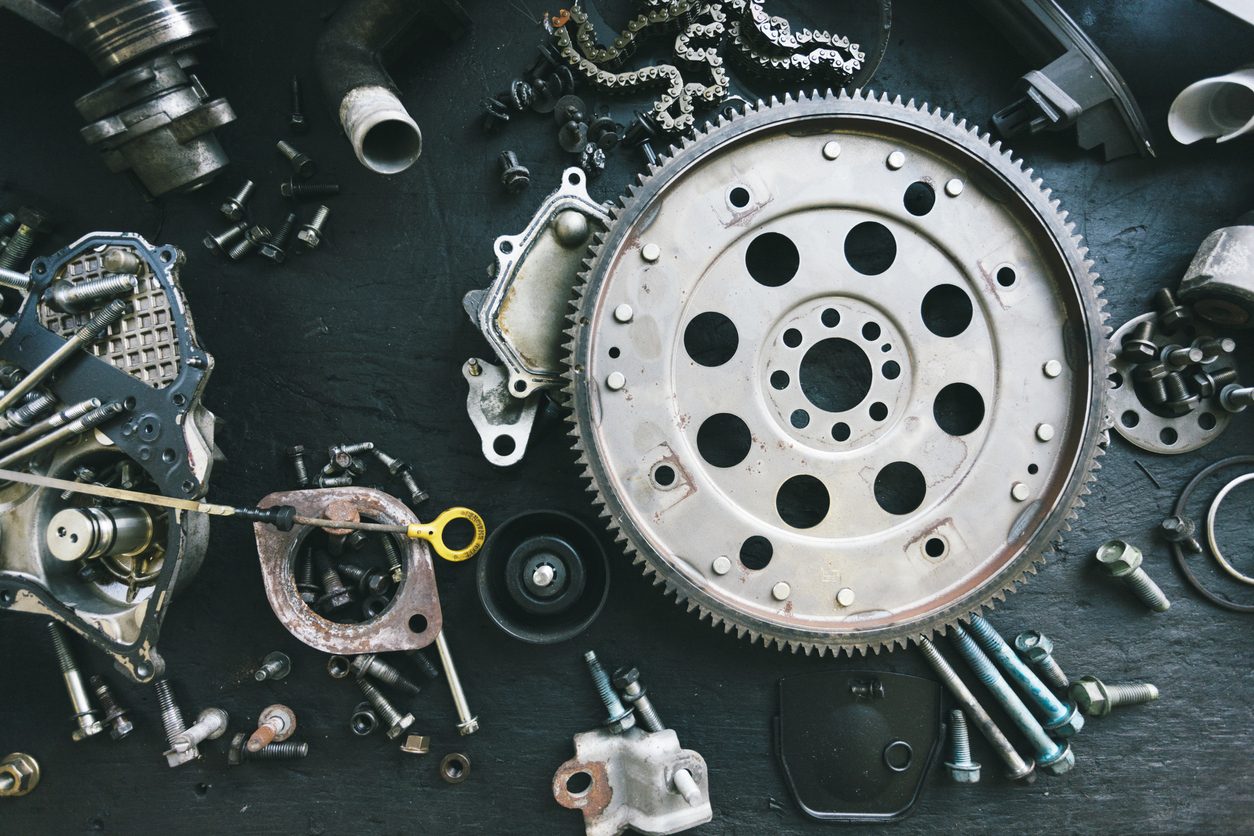

Source: cartakeback.com

Recycling plays an important role in starter motor production, as it can help reduce the environmental impact of this industrial process. By reusing materials and components, companies can cut down on waste and create greener products.

The benefits of recycling in starter motor production include reduced emissions from manufacturing processes; access to cheaper raw materials; improved safety for workers due to fewer hazardous chemicals involved; and an overall reduction in energy consumption. In addition, recycling helps protect precious natural resources by reducing the amount of mining required for new resources.

Finally, companies that use recycled parts benefit from a reputation boost among consumers who value sustainability practices. Recycling is thus essential for creating sustainable starter motors while also providing economic savings that businesses can pass on to their customers.

Challenges of Sustainable Car Practices

As starter motor production increases to meet the demands of the automotive industry, manufacturers need to consider the environmental impacts of their products. One way they can do this is through sustainable practices such as recycling and sustainability initiatives.

While these practices often have positive outcomes for the environment, there are still challenges associated with them that need to be addressed. One challenge is cost-effectiveness.

Sustainable practices may require additional investments in terms of equipment or labor costs which can increase operational expenses significantly.

Additionally, most recyclable materials used may not be readily available in certain areas or countries leading to expensive imports that may again result in increased costs and lower profit margins for producers.

Another issue related to sustainable car practices is quality control. Car parts produced from recycled materials must adhere strictly to safety standards set by governments and regulatory agencies if they are going to be accepted by consumers worldwide.

If recycling processes lead to sub-standard parts due to contamination, then companies would have wasted resources on a process that has no tangible results other than potential damage being done both financially and environmentally.

Finally, supply chain management also plays an important role when it comes to implementing successful recycling strategies within car manufacturing facilities. As many components used in starter motors come from different vendors around the world, coordinating these activities properly can become increasingly difficult given time constraints and limited resources .

Companies should therefore plan ahead by developing efficient systems that enable them track deliveries accurately while minimizing delays between suppliers and production lines.

Source: articles.stringo.com

Strategies for Improving Car Sustainability with Starter Motors

When it comes to improving sustainability with starter motors, there are a few effective strategies that can be implemented. One of the most important is utilizing recycled materials in production processes whenever possible.

This not only reduces the amount of resources required for manufacturing but also helps reduce emissions released during production.

Additionally, manufacturers should employ energy-efficient design practices when creating starter motors, such as using lightweight materials and incorporating advanced technologies like brushless motors into their designs.

Finally, businesses should strive to improve product durability by ensuring proper maintenance and repair protocols are put into place over time – this will help extend the lifespan of each motor used while reducing waste and environmental impacts associated with frequent replacements.

By implementing these strategies, companies can ensure theyre doing their part to promote sustainable motor production practices and reduce their carbon footprint in the process.

Conclusion

Source: cartakeback.com

The production of starter motors is a major contributor to environmental pollution. Through the implementation of recycling and sustainability practices, however, many companies have been able to reduce their carbon footprint while still producing high quality products.

By using recycled materials in starter motor production and adopting sustainable manufacturing methods, these companies are helping ensure that future generations can enjoy clean air and water for years to come.

Additionally, by incorporating car alternator technology into their products, these businesses are further reducing emissions from vehicles on the road today.

As more businesses embrace green practices in their operations, we can expect improved environmental outcomes around the world.