Linear actuators are essential components for any car modification, but are you aware of the common mistakes that can jeopardize your project? There’s a lot to consider when selecting the right linear actuator, and making an uninformed choice can lead to costly and even dangerous consequences.

Not all linear actuators in the market are created equal. Like most other products, they’re also substandard ones that may cause internal problems to your car. So when buying, watch out for those ones!

When it comes to choosing linear actuators for your car, there are several factors to keep in mind. You can determine the right linear actuators through their features, specifications, design, and type. Here, we explore the common mistakes to avoid when selecting linear actuators for your car, so you can make an informed decision and achieve the best possible results.

Factors To Consider When Choosing The Right Actuators

Critical information must first be ascertained to choose the best linear actuator for your vehicle. Factors such as operation speed, accuracy, and load capacity have to be identified and quantified.

1. Operation Speed

Generally, the maximum speed for belt drive actuators is five m/s. However, the guide system, which most commonly uses recirculating bearings, affects the limit. On the other hand, ball screw actuators should reach operating speeds of up to 1.5 m/s at stroke lengths of less than 1 meter.

2. Travel, Repeatability, and Positional Accuracy

In travel accuracy, the saddle or carriage is located in space during movement. Repeatability is the rate at which the actuator achieves a similar position with each stroke. Positioning accuracy is the rate at which the actuator reaches the target position.

Travel accuracy is largely influenced by the actuator’s base, structure, and mounting. Positional accuracy and repeatability are the main functions of the drive mechanism. So a good linear actuator should be able to pass all these accuracy tests.

3. Load Capacity

Linear actuators can have load capacities ranging from a few pounds to several thousand pounds. Only choose an actuator with a load capacity that surpasses the maximum weight of the load it’ll be moving and any additional forces. This will ensure safe and reliable operation.

Mistakes to Avoid When Buying Linear Actuators

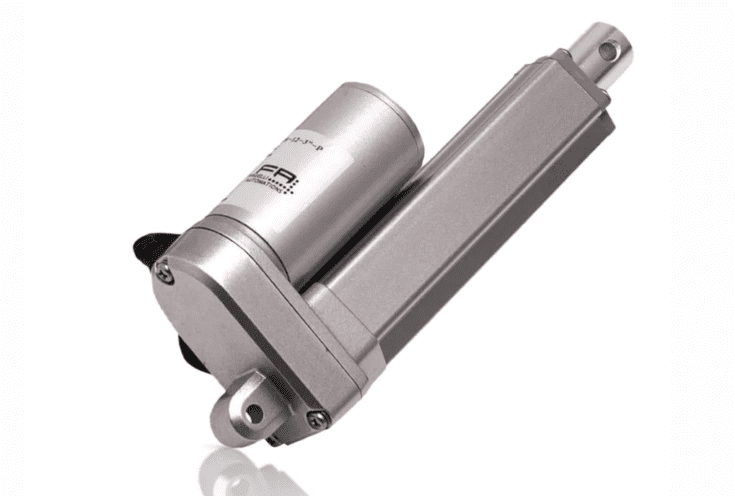

- Ensure that the linear actuator you are buying is made of quality aluminum alloy. If unsure, review the material certificate.

- Do not buy a linear actuator without verifying the data in the spec sheet. This includes the load capacity and stroke length needed.

- Choosing a low-quality actuator to save money, which can result in failure and costly repairs.

- Choosing the wrong type of actuator for the application (e.g. choosing an electric actuator when hydraulic is needed).

- Buying from unknown sources.

Conclusion

When buying the right linear actuators for cars, the factors to consider hover around the performance level. Therefore, a good linear actuator should be able to produce the right speed level. Other considerations are accurate positioning, repeatability and maximum load capacity.

Also, when buying a linear actuator, verify its specifications, features, and design. Ensure they meet the minimum requirements. Most importantly, remember to only buy from a trusted manufacturer to avoid damage to your systems.